Laservermessungen

mit Renishaw Laser ML 10

inkl. Kalibrierschein

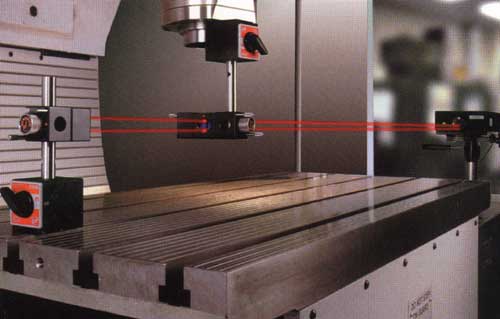

Lineare Abstandsmessung

Mit unserem Laser-Interferometer-System messen wir die Positioniergenauigkeit und die Wiederholgenauigkeit durch Vergleich zwischen dem von Ihrer Maschine angezeigten Positionswert und der tatsächlichen Position. Diese werten wir für Sie auf Wunsch am PC statistisch aus.

Hier auf dem Bild sehen Sie z. B. eine Positionsmessung in der X-Achse einer Fräsmaschine.

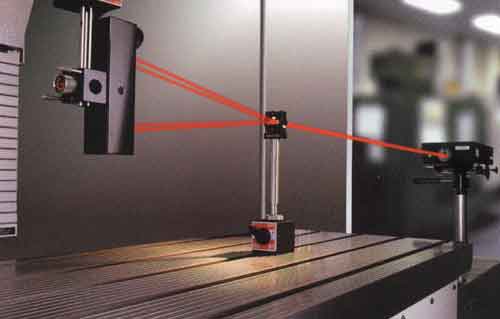

Winkelmessungen bis 40 mm

Hier wird der Winkelfehler von zwei nominell orthogonalen Achsen durch den Vergleich zweier Geradheitsmessungen ermittelt. Rechtswinkligkeitsfehler haben einen direkten Einfluss auf die Positioniergenauigkeit einer Maschine.

Auf dem Bild: Messung der Rechtwinkligkeit zwischen der X- und Z-Achse an einem Bearbeitungszentrum.

Geradheits- und Parallelitätsmessungen bis 20 mm

Zur Ermittlung der horizontalen und vertikalen Geradheit der Führung einer Maschine wird die Geradheitsmessung verwendet. Die Positionierungsgenauigkeit und die Bahngenauigkeit hängen davon ab.

Auf dem Bild: Geradheitsmessung an einem BAZ mit fahrendem Tisch.

8 - 16 Uhr